As we transition into the Industrial 4.0 era, the demand for advanced technologies that enhance operational efficiency and reliability has never been greater. One of the key components driving this transformation is the printed circuit board (PCB). High-performance hybrid rigid-flex circuit boards are emerging as a crucial element in modern industrial automation processes, providing the necessary quality and performance to adapt to evolving manufacturing needs.

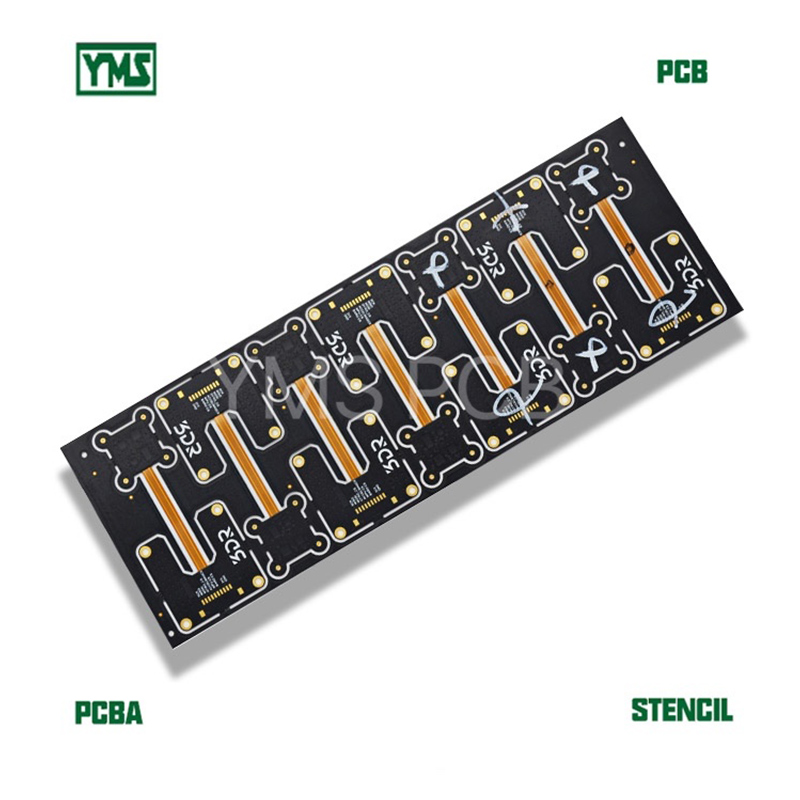

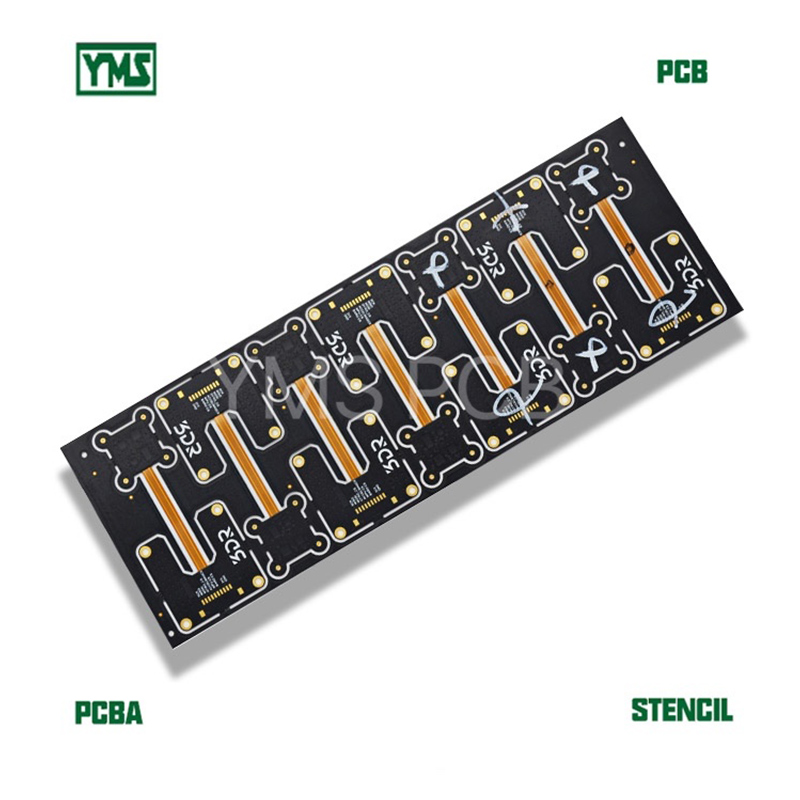

These hybrid PCBs combine the flexibility of flexible printed circuit boards with the rigidity of traditional rigid boards, enabling manufacturers to create intricate designs that are lightweight yet robust. This hybrid approach not only simplifies assembly but also minimizes space constraints within complex machinery.

High-performance hybrid rigid-flex PCBs offer numerous benefits in the industrial sector, including:

Data shows that manufacturers utilizing hybrid rigid-flex PCBs can experience up to 30% improvement in production efficiency, directly impacting the bottom line. As reliability becomes a focal point in automation systems, investing in these advanced PCBs ensures that companies can meet the stringent demands of Industry 4.0.

In conclusion, high-performance hybrid rigid-flex circuit boards are indispensable in navigating the complexities of industrial automation. Their ability to integrate seamlessly into diverse applications, combined with their high reliability, positions them as an essential component in achieving the efficiencies demanded by Industrial 4.0.