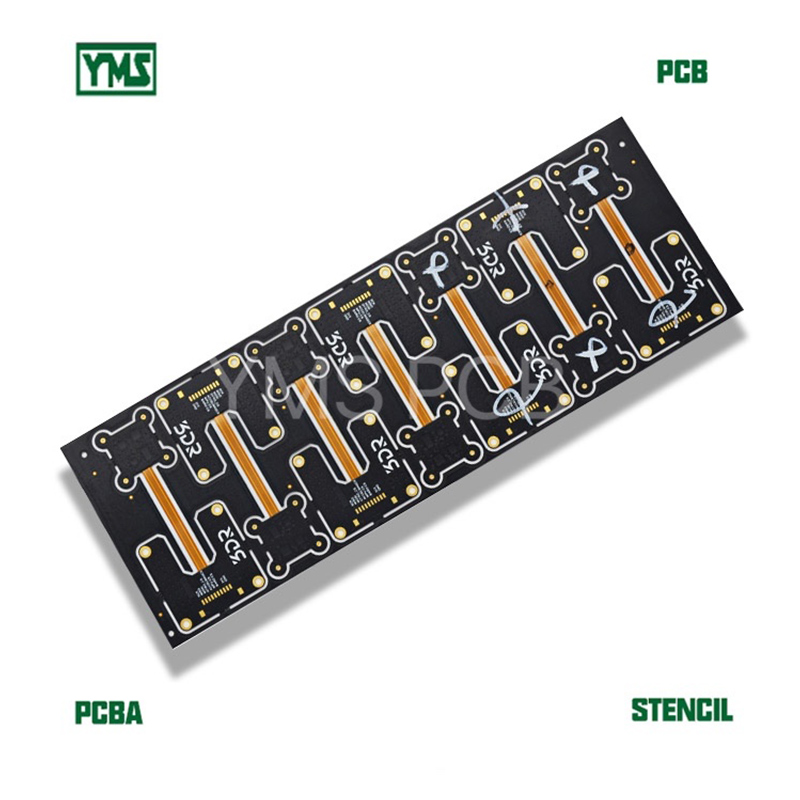

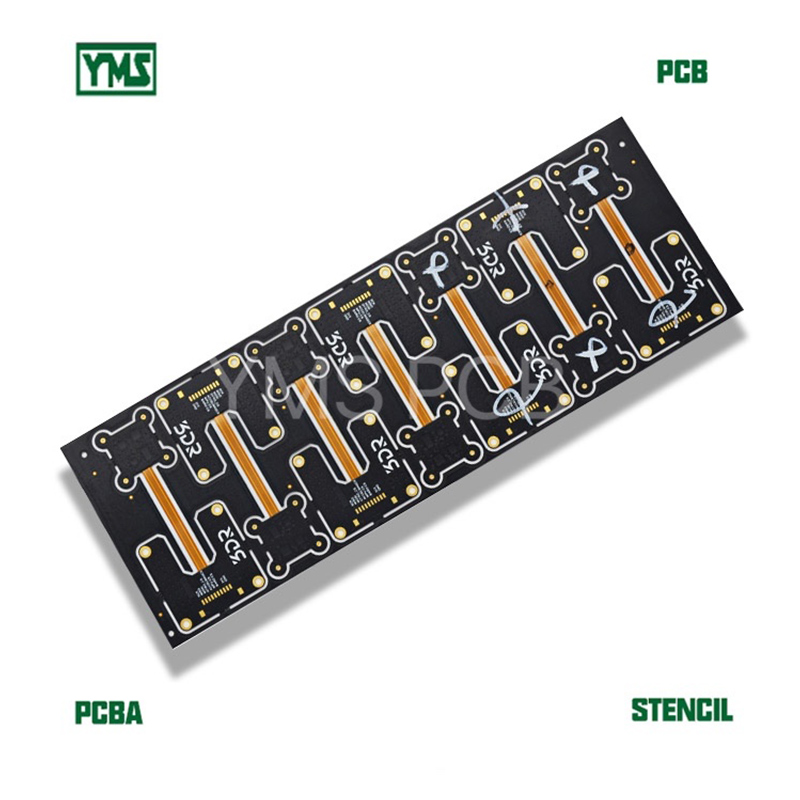

As we move deeper into the era of Industry 4.0, the demand for advanced technologies is at an all-time high. Among these innovations are high-performance flexible printed circuit boards (PCBs) that play a crucial role in enhancing industrial automation. These boards not only offer superior flexibility and space-saving designs but also contribute significantly to the reliability and efficiency of automated systems.

Reliability is a non-negotiable factor in industrial automation. High-performance PCBs are engineered to withstand harsh operational conditions, ensuring that machinery operates seamlessly. Statistics show that industries implementing high-reliability PCBs experience up to a 25% reduction in equipment failures. This statistic underscores the critical role that quality PCBs play in minimizing downtime and enhancing productivity.

The competitive landscape of modern manufacturing demands adaptability. Flexible PCBs allow for intricate designs and complex functionalities in a compact form factor. This adaptability translates to lower production costs and shorter product development cycles. In fact, businesses report that the integration of flexible PCBs results in a 30% faster time-to-market for new products.

As automation continues to evolve, the role of advanced PCB technology will only grow more prominent. By leveraging high-performance flexible PCBs, companies can not only improve operational efficiency but also foster innovation. Embracing these cutting-edge technologies is key to achieving sustainable growth and maintaining a competitive edge in the industrial sector.