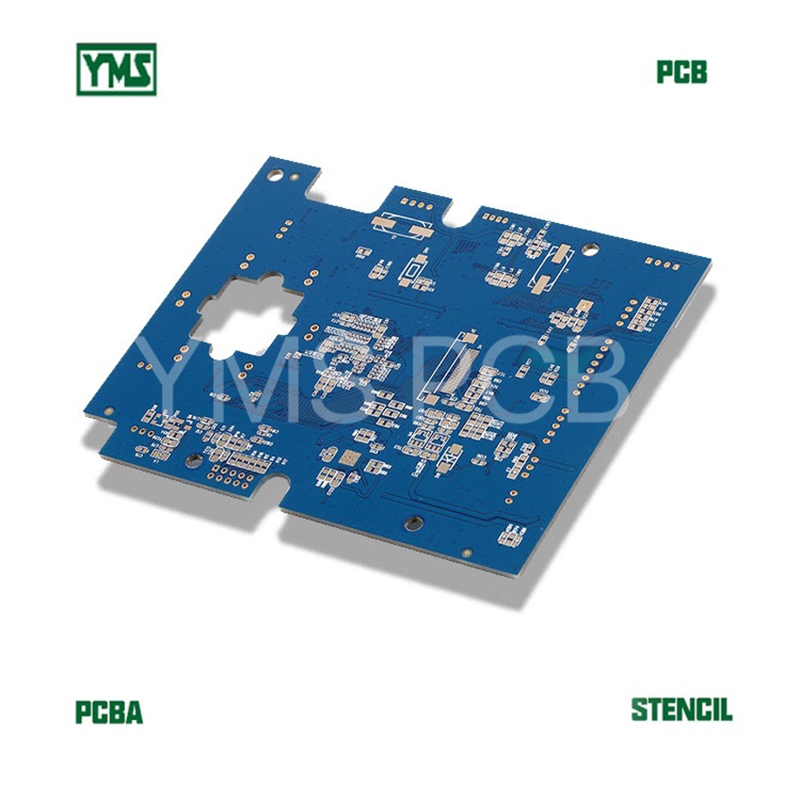

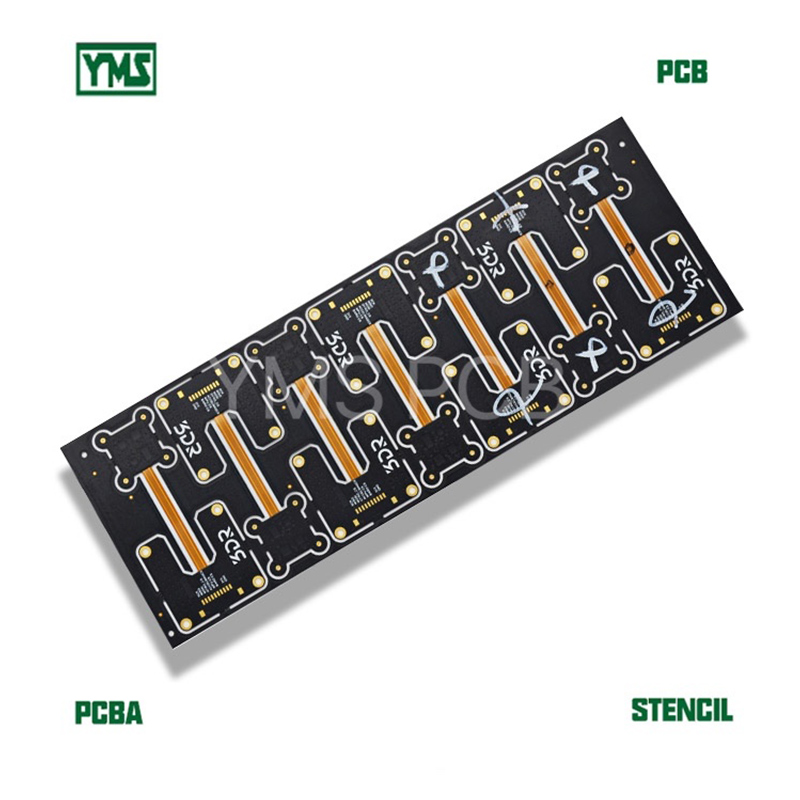

The ultimate performance mixed hard-flex printed circuit board (PCB) represents a significant advancement in PCB technology, featuring an intricate 8-layer structure. This innovative design integrates six rigid PCB layers and two flexible layers, providing exceptional mechanical strength and superior electrical performance critical for modern high-tech applications.

Utilizing state-of-the-art MITSUBISHI laser drilling technology, our PCBs enable precise dual-step laser hole processing, ensuring the most intricate designs are achievable. The application of blind buried hole technology (VIA in pad process) enables high-density interconnection (HDI) suitable for cutting-edge electronic applications.

Our boards feature ENIG (Electroless Nickel Immersion Gold) surface treatment, enhancing solderability and long-term reliability. Customizable impedance control options ensure signal integrity is maintained, making them ideal for high-frequency transmission environments.

Additionally, BGA (Ball Grid Array) resin filled hole technology supports small-pitch BGA packaging, optimizing assembly density and stability. Compliance with RoHS and REACH environmental standards positions our PCBs as part of the green electronics manufacturing trend.

These high-performance PCBs are tailored for a wide range of industries:

In conclusion, our premium performance mixed hard-flex PCBs stand at the forefront of technological advancement, catering to the sophisticated needs of the electronics industry while ensuring environmental responsibility and superior performance.