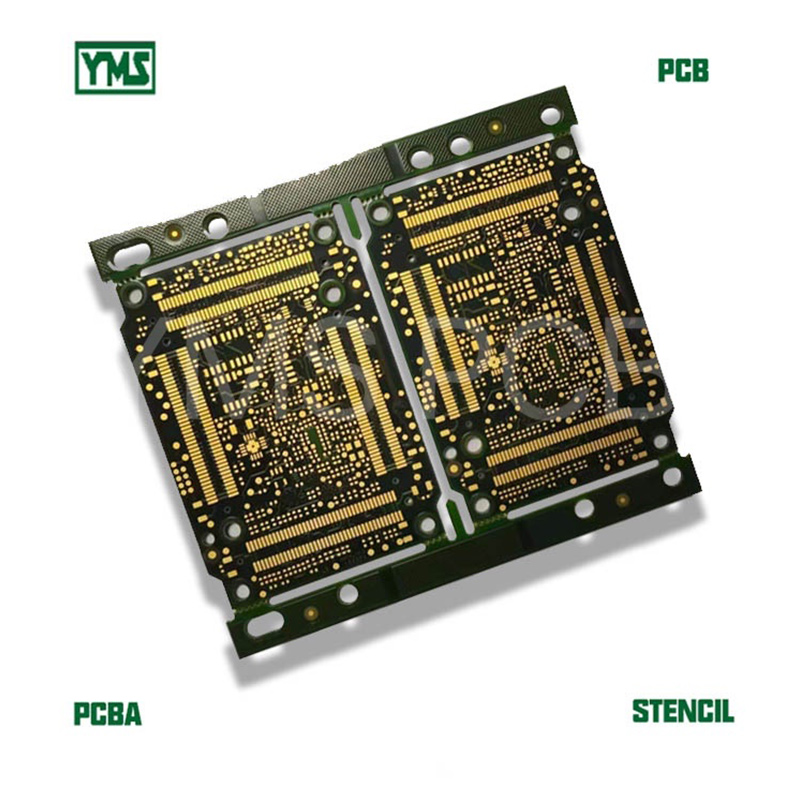

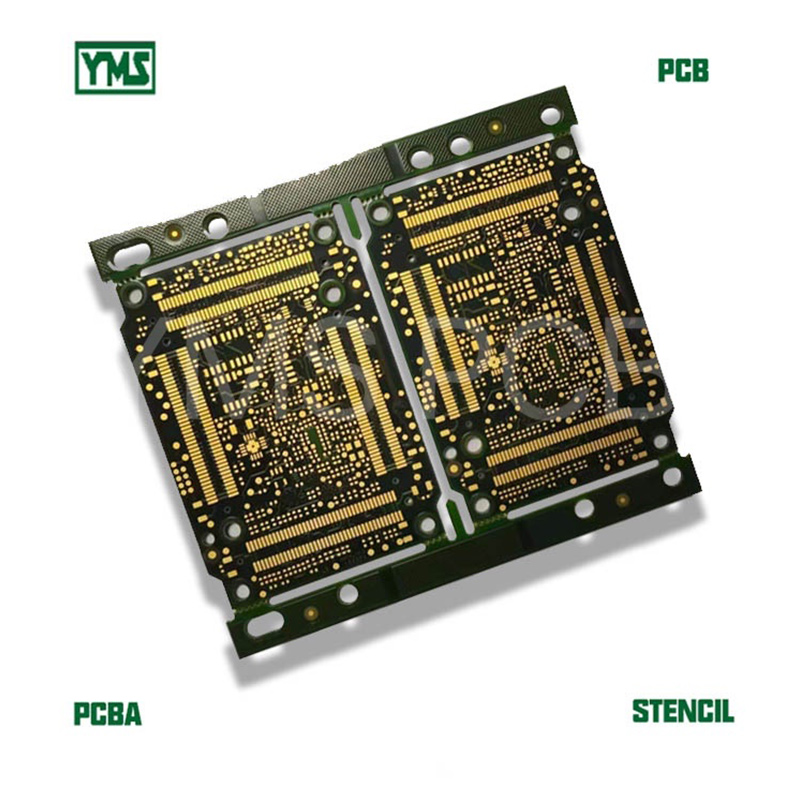

In the rapidly evolving landscape of industrial automation, technology plays a pivotal role in enhancing efficiency and reliability. Among these advancements, the 8-layer rigid-flex printed circuit boards (PCBs) stand out as a revolutionary component. By leveraging advanced High-Density Interconnect (HDI) technology, these PCBs are engineered to meet the demanding requirements of modern control systems.

The integration of 8-layer rigid-flex PCBs into industrial automation systems facilitates superior efficiency. These boards allow for compact designs that reduce the weight and size of electronic assemblies, making them ideal for environments where space is a premium. This efficiency in design does not come at the expense of performance; rather, it ensures that systems operate seamlessly and reliably.

Reliability is the cornerstone of any automation system. The use of HDI technology in the manufacturing of 8-layer rigid-flex PCBs enhances electrical performance. This technology enables designers to create smaller trace widths and spacings, facilitating communication between components at a faster rate without sacrificing quality. In environments such as manufacturing plants, where downtime can lead to significant losses, the reliability offered by these PCBs is unparalleled.

In conclusion, the advent of 8-layer rigid-flex PCBs is transforming the industrial automation sector. Their ability to enhance efficiency and offer reliability through advanced HDI technology empowers industries to achieve greater performance levels while optimizing their operations. As industries continue to embrace these technological advancements, the future of industrial automation looks promising.