In the fast-paced realm of medical electronics, finding the perfect balance between functionality and reliability is crucial. The introduction of four-layer rigid-flex PCBs is transforming how medical devices are designed and manufactured. These innovative PCBs not only enhance the performance of medical devices but also cater to the ever-growing demands for customization. 🚀

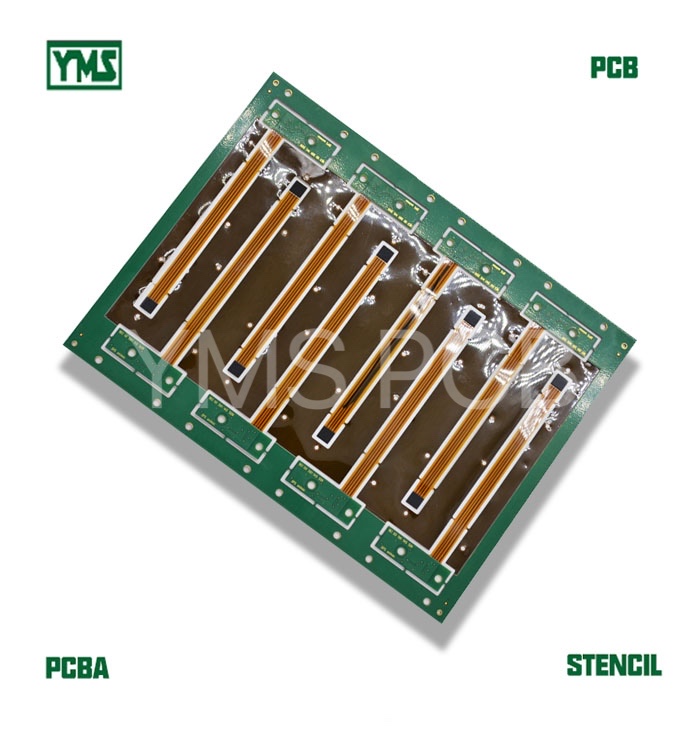

With the increasing complexity of medical devices, there is a heightened need for high reliability in their electronic components. Four-layer rigid-flex PCBs are specifically designed to meet these needs by combining the best attributes of both rigid and flexible boards. They allow for intricate layouts while maintaining structural integrity, making them ideal for devices where space is a premium.

These PCBs not only ensure durability but also significantly reduce the weight of medical equipment—an important factor for ease of use. Smarter designs lead to better patient outcomes, which is what we all aim for in the medical industry. Whether it’s in imaging systems or portable monitoring equipment, our customized PCB solutions are paving the way for innovations that save lives. 💚

In conclusion, investing in tailored PCB solutions will keep your company ahead of the game in the medical electronics industry. These high-performing, balanced solutions not only cater to the customization needs but also ensure the reliability that’s paramount for medical applications. Let's embrace the future of medical technology together! 🚀