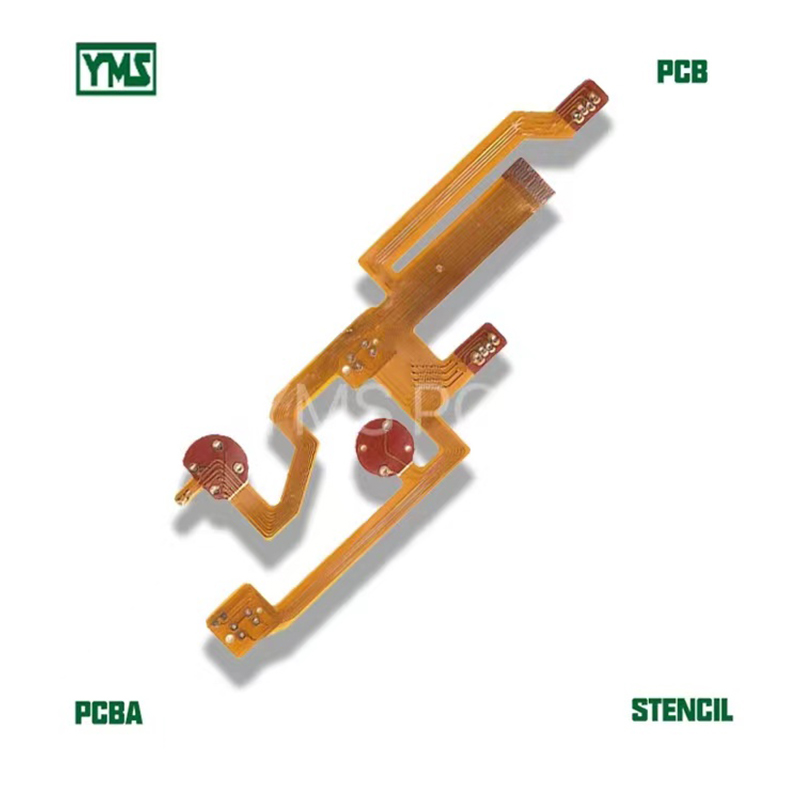

Flexible printed circuit boards (FPC) are revolutionizing the electronics industry, especially in applications requiring high reliability and precision. Manufactured from polyimide (PI), these boards offer remarkable flexibility and durability, making them essential for a range of products including smartphones, laptops, and sophisticated medical devices.

1. Superior Flexibility: Utilizing PI as the substrate ensures exceptional bending and folding capabilities, ideal for compact assembly and space-restricted designs.

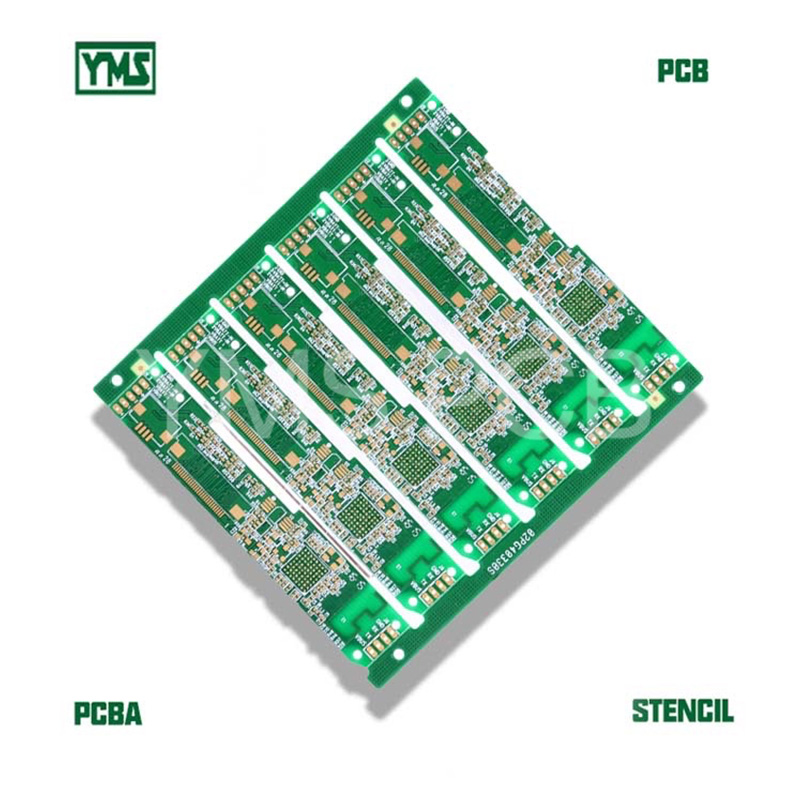

2. Precision Circuit Design: Advanced manufacturing technology enables a minimum line width/spacing of 0.05mm (2mil) and a minimum drill hole of 0.15mm (6mil), meeting the demanding requirements for high-precision circuits.

3. High-Quality Surface Treatment: The ENIG (Electroless Nickel/Immersion Gold) surface treatment enhances soldering performance and long-term circuit reliability.

4. Customized Solutions: From single-sided to multi-layer boards, we provide integrated assembly services, including SMT, DIP, and functional testing to cater to diverse customer needs.

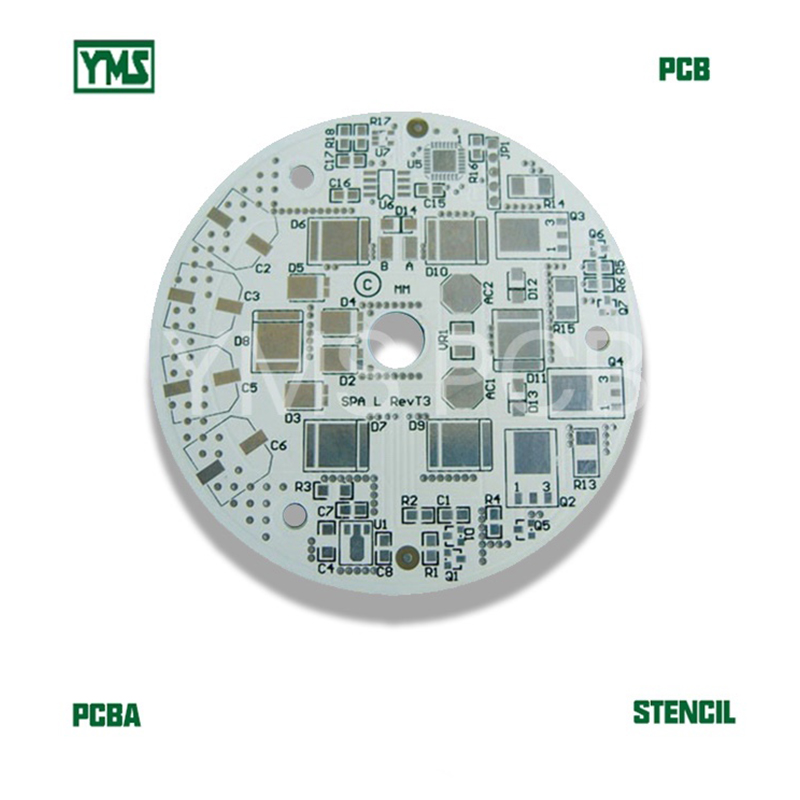

Flexible PCBs find vast applications in:

1. Portable Electronics: Perfect for smartphones, laptops, and wearable devices, aligning with the demand for lightweight and compact designs.

2. Industrial and Automotive Applications: Widely used in industrial control systems and automotive sensors, offering durable and reliable circuit solutions.

3. Medical Devices: Suitable for high-sensitivity monitoring and diagnostic equipment, fulfilling the unique requirements for flexibility and accuracy in the medical sector.

4. High-End Consumer Electronics: Ideal for built-in LED displays and electronic chargers, ensuring advanced performance and user satisfaction.

With unmatched flexibility, precision, and customization options, our high-performance flexible PCBs stand at the forefront of modern electronics. Explore how these cutting-edge solutions can elevate your products and drive innovation in your industry.