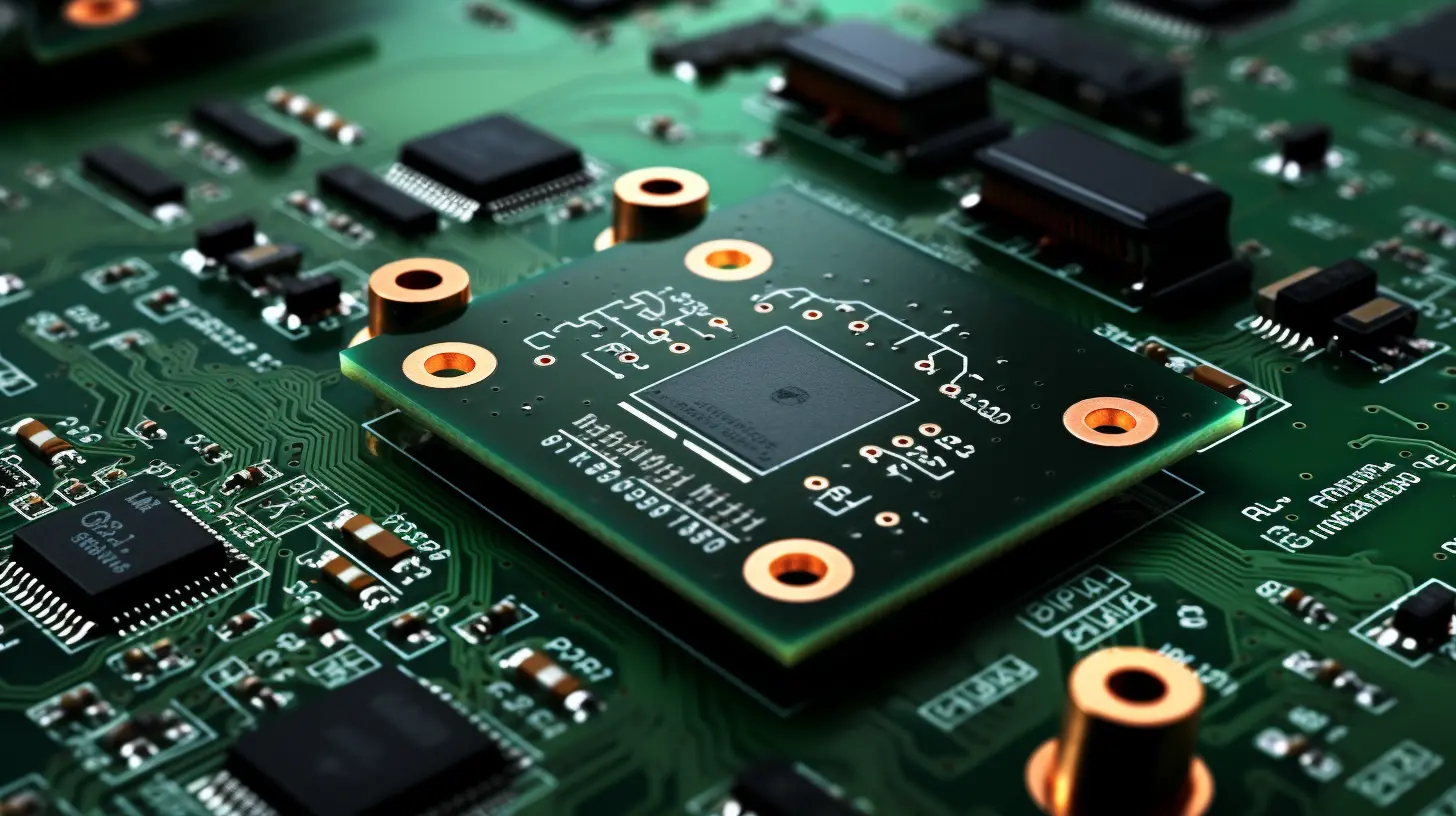

In the rapidly evolving world of electronics, enhancing the performance of printed circuit boards (PCBs) is essential. Two popular surface finish technologies, OSP (Organic Solderability Preservative) and ENIG (Electroless Nickel Immersion Gold), play a significant role in improving solderability and overall functionality. This article dives into the advantages of these finishes and how they can be effectively utilized in flexible and rigid-flex PCBs, helping manufacturers achieve superior results and meet modern application demands.

Organic Solderability Preservative (OSP) is a water-based organic coating that provides a barrier against oxidation and preserves the solderability of the PCB surface. One of its main benefits is its environment-friendly composition, making it ideal for companies aiming to adhere to sustainability practices.

On the other hand, Electroless Nickel Immersion Gold (ENIG) involves applying a nickel layer followed by a thin layer of gold. This method provides excellent solderability, corrosion resistance, and durability. ENIG finishes are particularly beneficial for PCBs that require fine pitch components and high-density interconnects due to their excellent surface planarity.

Combining OSP and ENIG finishes can yield remarkable results for both flexible and rigid-flex PCBs. The integration of these surface finishes allows manufacturers to take advantage of the strengths of both technologies, maximizing performance while minimizing potential reworks and failures.

According to recent studies, PCBs treated with both finishes showed a 30% improvement in solder joint reliability compared to those with single coatings. Additionally, the combination helps in achieving reduced manufacturing costs due to fewer defects and reworks, making it a crucial choice for industry leaders aiming to stay competitive in today's market.

In conclusion, the integration of OSP and ENIG finishes in the manufacturing of PCBs serves as a powerful strategy to enhance performance, reliability, and solderability. By leveraging these advancements, electronics manufacturers can meet the stringent requirements of modern applications, ensuring long-term success and a competitive edge in the market.

With the increasing demand for high-quality PCBs, understanding the benefits and application of OSP and ENIG finishes will equip manufacturers with the insights needed to thrive in a dynamic industry.