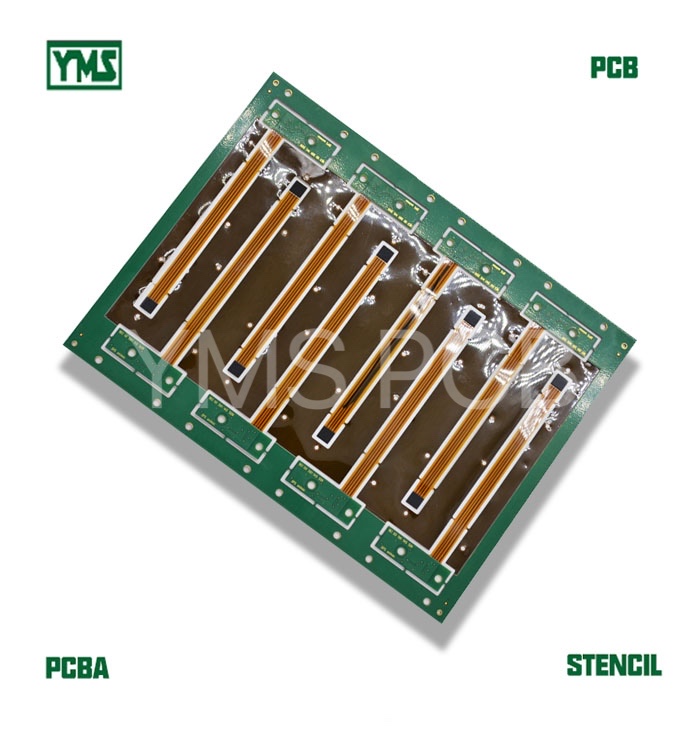

Four-layer rigid-flex boards represent a significant advancement in PCB technology. By combining flexible and rigid layers, these boards provide durability while allowing for versatile design options. This combination is especially beneficial in applications requiring high-density interconnections, such as in antenna and power module designs.

The unique structure of four-layer rigid-flex boards offers numerous advantages. They facilitate reduced weight and space-saving designs, crucial for modern electronics. Additionally, these boards improve signal integrity, enabling better performance of antennas and power modules. As a result, engineers can develop more compact and efficient electronic devices that meet the evolving demands of the industry.

In antenna technology, four-layer rigid-flex boards are being employed to create sophisticated designs that enhance performance. The flexibility of these boards allows for unique shapes and configurations that improve the radiation characteristics of antennas. This capability has led to advancements in wireless communication technologies, crucial for both consumer and industrial applications.

Similarly, in power modules, these PCBs contribute to the compact and efficient design. The integration of power management circuitry onto the rigid-flex boards reduces assembly time and components needed, leading to cost savings. This trend is vital as the demand for miniaturization in electronic devices continues to grow.

In conclusion, four-layer rigid-flex boards are redefining what is possible in complex electronic applications, particularly in antenna technology and power modules. Their innovative designs and advantages not only enhance performance but also pave the way for future developments in electronics. Understanding these benefits is key for companies looking to stay competitive in a rapidly evolving market.