In the rapidly evolving electronics industry, the demand for high-performance and reliable multilayer PCBs is at an all-time high. Advanced manufacturing technologies play a pivotal role in meeting these demands. This article will explore innovative solutions in multilayer PCB manufacturing, focusing on their benefits in performance and reliability.

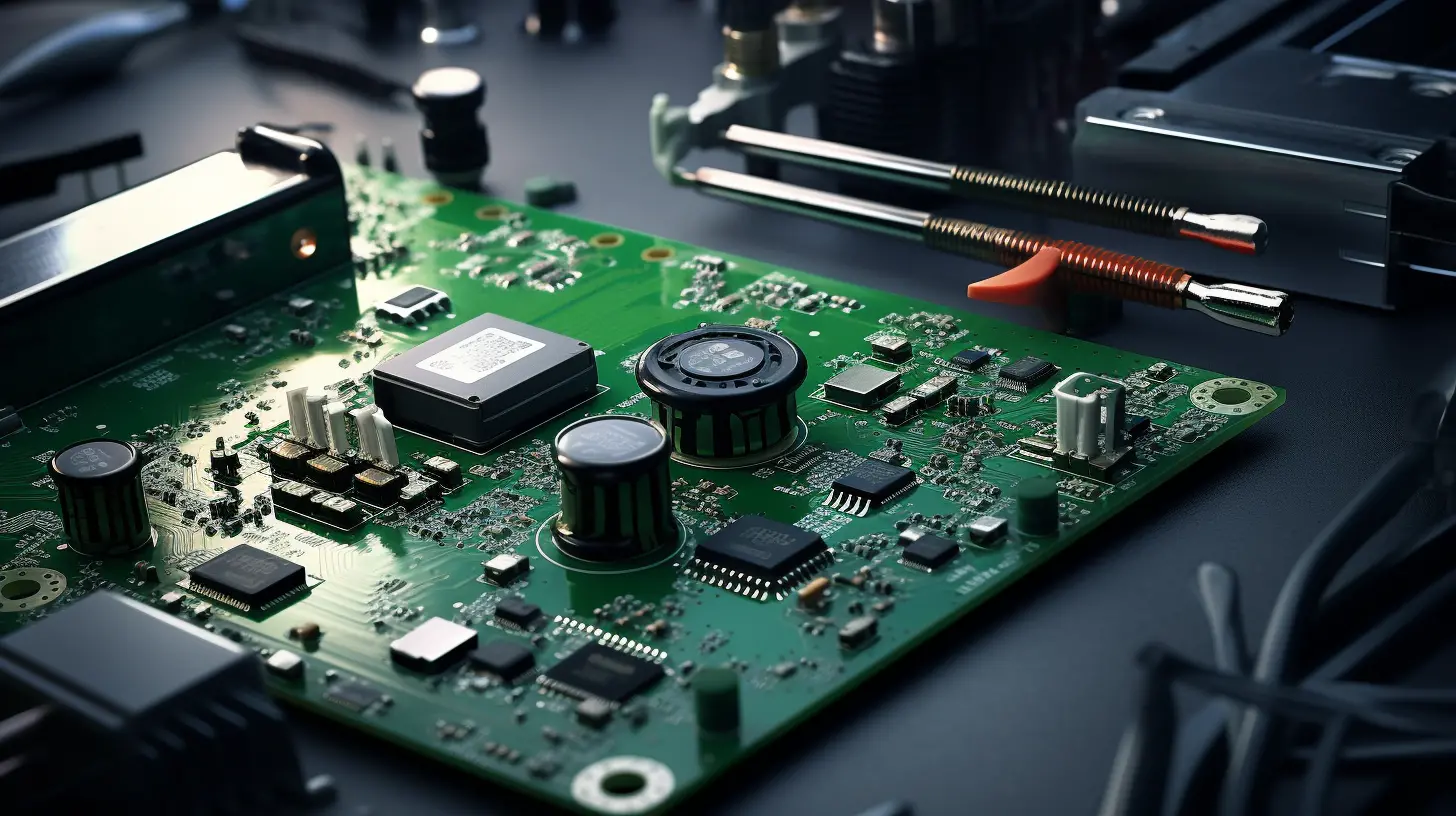

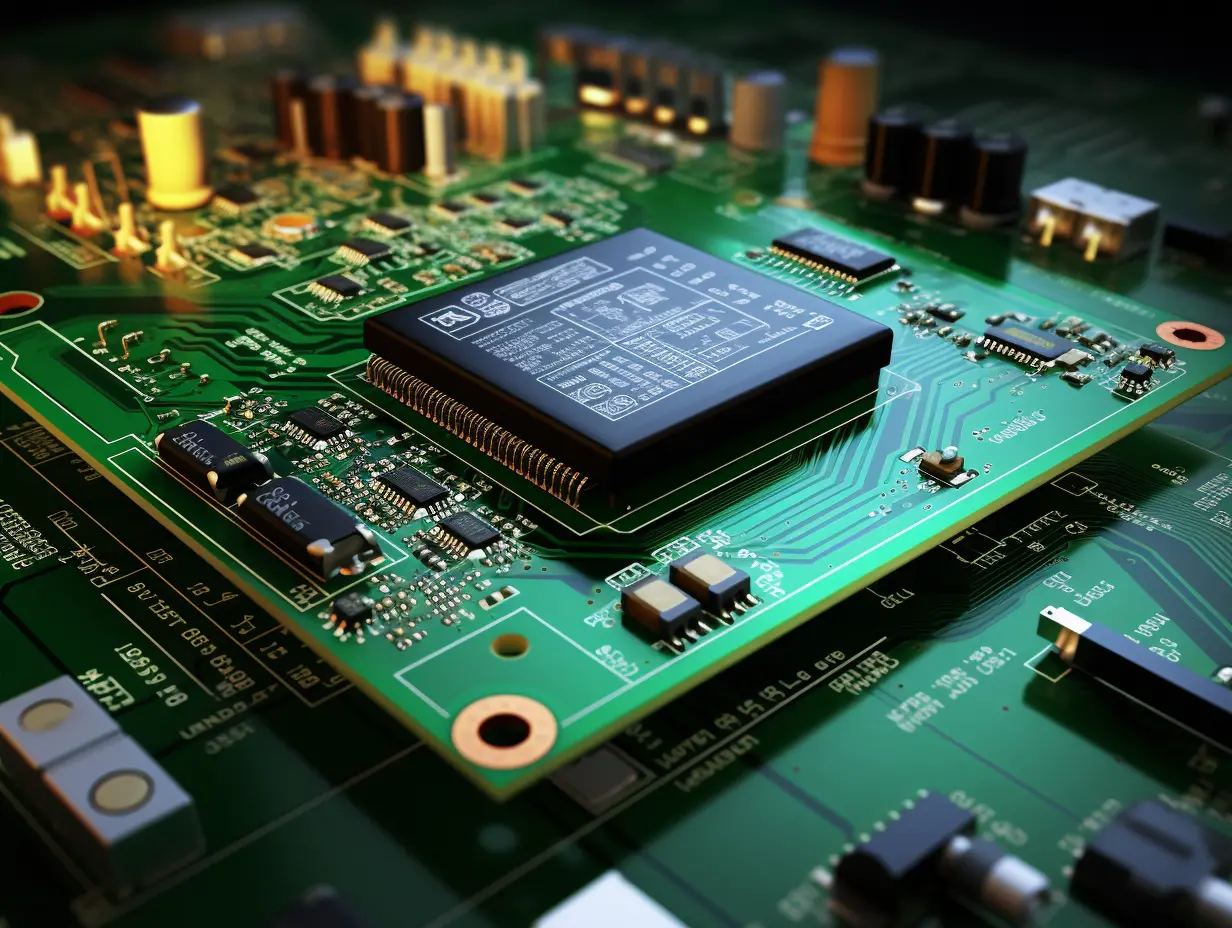

The complexity of modern electronics requires multilayer PCBs that can support increased functionality while maintaining compact designs. Advanced manufacturing processes, including laser drilling and high-density interconnect (HDI) technologies, allow for the creation of intricate patterns essential for today’s devices.

1. Performance: Advanced PCB manufacturing processes improve the electrical and thermal performance of PCBs, ensuring that they can handle the demands of high-speed electronics.

2. Reliability: The precision engineering involved in advanced PCB technology results in lower failure rates and longer product lifespans.

3. Cost-Effectiveness: Although the initial investment in advanced manufacturing technology can be significant, the efficiency and quality improvements lead to reduced long-term costs.

As the demand for multilayer PCBs continues to grow, adopting advanced manufacturing solutions will position companies for future success. By leveraging modern technology, businesses can enhance their product performance and reliability within the competitive electronics market. Embracing innovation is the key to staying ahead.